金属密封浮动、固定式球阀

ANSI VI 级密封性能 采用先进的球体研磨工艺球体和密封面达到极高的圆度和光洁度。

球体和阀座硬化技术 超音速喷涂、镍基喷焊、硬质合金喷焊、高强高硬陶瓷加工的球体和阀座,表面硬度达到HRC60~74,耐温540℃,最高980℃。

防止阀门高温时胀卡 采用专利技术高温时,零部件膨胀量,由特殊结构吸纳,使开关灵活。

密封紧急救护 高压固定式球阀带有密封注脂孔,可修补密封面,保证密封还可清洗阀腔密封面。

ANSI VI Leakage Advanced ball skiving craft, between the ball and the seal face, there appears roundness and cleanness.

Vulcanize techniques on ball and seat ring HRC60~74 on the surface, 540℃-980℃

Prevent bulge when meet high temperature Adopts patent technical, the bulge of the parts was absorbed by special machinery, open and close flexibly

Repair seal the seal face can be repaired

☆固定球阀球前双向密封 ☆球腔内超压释放功能 ☆自然防静电结构 ☆防火安全设计

Double directions seal pressure relief prevent static structure Fireproofing design

密封性能可靠(见图一):PTFE弹性材料密封圈嵌于不锈钢阀座内,金属阀座尾端设有弹簧保证密封圈足够的预紧力,阀门在使用过程中密封面磨损时,在弹簧作用下阀门继续保证良好的密封性能。

防火结构(见图二):为防止由于骤热或火灾的出现,使聚四氟乙烯密封圈烧毁,发生较大泄露,而助长火势,在球体与阀座间设置防火密封环,在密封圈烧毁时在弹簧力作用下,将阀座密封环迅速推向球体上,形成金属与金属密封,起到一定程度的密封效果。耐火试验符合API 6FA和API 607标准要求。

Seal is reliability (Picture one): PTFE O-ring was set in stainless steel seat ring, and there is spring at the end which makes the seal ring have enough tighten. Under the action of the spring the valve still has a good seal when the seal face is abrade.

Airproofing structure(Picture two):In order to prevent heat and fire from burning Teflon which makes leakage, fostering fire, we set fireproofing seal ring. When the seal ring was burnt, at the action of the spring, it drives the seal ring to the ball which makes the metal touches with each other. Fireproofing testing comply with API 6FA and API 607

|

|

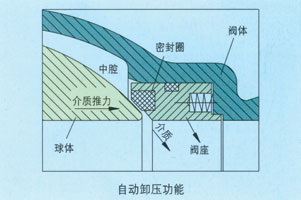

自动泄压功能(见图三):当阀门中腔停滞的介质压力异常升高超过弹簧的预紧力时,阀座后退脱离球体,达到自动卸压的效果,卸压后阀座自动复位。

可修补密封面(见图四):本阀门设计有辅助的阀座紧急密封系统,一旦密封受损或出现紧急情况而不能密封时,通过辅助密封系统向密封面注射相应的密封剂即可修复密封面,达到紧急密封。当输送的介质不洁或含有少量颗粒时,为保护密封面,确保达到可靠的密封,还可给这一装置注射相应的清洗剂或润滑剂对密封面进行清洗。

Pressure Relief Automatically (Picture three):When the pressure inside the valve is much higher which exceeds the spring’s power, the valve seat is back ,breaking away from the ball. The pressures can relief automatically. At the same time, the seat is able to return automatically.

Seal face can be repaired (Picture Four): This kind of valve has assistant seal system. In case of emergency or the seal is damaged, the assistant seal system can repair the seal face. When the operating medium contains some granules, you can squirt lotion or lubricant to clean the seal face, making sure a reliable seal.

|